An industrial coating is a paint or coating defined by its protective, rather than its aesthetic properties, although it can provide both. The most common use of industrial coatings is for corrosion control of steel or concrete. Industrial coatings are used in production plants and by qualified applicator shops to coat discrete parts, finished assemblies (automobiles, trucks, aircraft, vessels), tanks, piping, metal sheet, continuous webs, wood panels, paper, and paperboard.

Types

Coatings can be classified into a number of categories based on their composition and function.

Lacquers – coatings made from the clear sap of the lacquer tree that produce a hard, durable finish to decorate and protect wood, metal, and other surfaces.

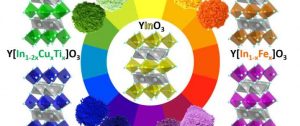

Paints – a large category of coatings including pigmented liquids or powders used to protect and/or beautify substrates. The two general classifications of paint are enamels and lacquers.

- Enamel paints both dry and cure once applied to a surface. They are extremely stable, and can last for decades if stored properly. They also have lower levels of volatile organic compounds (VOCs) and are more environmentally-friendly. Enamels dry/cure times are typically much longer than lacquers, but newer catalyst additions are reducing that time difference.

- Lacquer paints dry but do not cure. They dry harder, smoother, and more quickly than enamel paints and are easier to sand since enamels can be gummy; however, lacquer paints are not as tough and will chip or crack more easily than enamels.

Powder coatings – coatings which are applied as free-flowing, dry powders. These coatings are dry, meaning they don’t require a solvent to keep the components together. Powder coatings are applied using either an electrostatic spray (see image right) or a fluidized bed. Parts are heated before or after application to fuse the particles together and bind them to the surface.

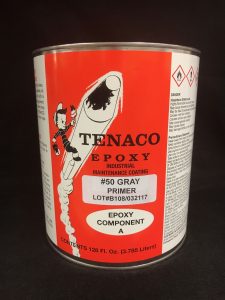

Primers – preparatory coatings that are applied to treat a surface before the application of another coating. They are primarily designed to increase coating adhesion to the substrate surface. Some primers also lend uniformity to the topcoat, inhibit corrosion of the substrate, and/or stop coating discoloration.

More Types

Sealers – coatings defined as surface sealants used to seal the substrate surface, providing protection from contamination and corrosion. They are applied to porous castings, powder metal parts, stator windings, and transformers to seal the surfaces and/or internal porosity by soaking into or impregnation through the open pores.

Stains – semitransparent or semisolid coatings used to accent wood grains and add protection. Semitransparent stains penetrate the wood without forming a film, allowing much of the wood grain to show through the finish. Semisolid stains act more like paints, forming a protective film and not deeply penetrating the wood.

Varnishes – transparent, hard, protective finish consisting typically of a drying oil, resin, and thinner or solvent. They are applied as liquids to wood or other materials to provide a colorless coating that protects from abrasion, chemical attack, water damage, and in some cases UV light.

Properties

The main purpose of industrial coatings is to add or enhance a material’s properties. Buyers should select coatings based on what properties are important to their specific application. Properties involving coatings include:

- Chemical resistant – coatings which resist acids, alkalis, oils, and general chemicals.

- Conductive – coatings used to form an electrically-conductive layer.

- Corrosion inhibiting – coatings which prevent moisture from reaching the metal or underlying substrate, or provide a sacrificial layer.

- Heat resistant – coatings resist damage from heat, or are formulated for use in high-temperature environments.

- Protective – coatings are designed to protect substrates and surfaces.

- Touch-up – coatings are used to repair and match the original coating where it has been damaged by scratching, corrosion, abrasion, erosion, scuffing, denting, chipping, delaminating, or other processes.

- Waterproof / water repellant – coatings are clear, exterior finishes that cause water to bead-up on the surface. They also minimize the penetration of water into the substrate.

- Wear resistant – coatings are designed to resist wear or erosion. Wear is caused by a sliding action between two or more components. Erosion is surface damage or material removal caused by the impact of particles or slurries.

- Weather resistant – coatings are weather-resistant or protect against damage from UV radiation.

Sources: Engineering 360 powered by IEEE GlobalSpec

Viking Paints, INC.

Start off by selecting color cards are your favorite home improvement store. Plan your color scheme and purchase paint prior to starting your project. To get a durable more family proof surface select a 100% acrylic latex paint in a glossier finish. This will make clean ups a breeze.

Start off by selecting color cards are your favorite home improvement store. Plan your color scheme and purchase paint prior to starting your project. To get a durable more family proof surface select a 100% acrylic latex paint in a glossier finish. This will make clean ups a breeze. Conquer the largest part of the wall first. It will cause instant gratification and make your time painting go more quickly.Apply a 3 to 5 inch strip of paint where the wall meets the ceiling, windows, door frames or molding. Roll on the paint in 3 X 3 sections. Apply the paint in “W” pattern, then fill the W with horizontal strokes. To establish your edges use an angled trim brush.

Conquer the largest part of the wall first. It will cause instant gratification and make your time painting go more quickly.Apply a 3 to 5 inch strip of paint where the wall meets the ceiling, windows, door frames or molding. Roll on the paint in 3 X 3 sections. Apply the paint in “W” pattern, then fill the W with horizontal strokes. To establish your edges use an angled trim brush. An epoxy coating is a two part product consisting of one part epoxy resin and one part polyamine hardener. Once this product is mixed you are on a race against time. Note that if your purchase a color epoxy you are actually tinting the resin. If no color is selected a resin will dry clear.

An epoxy coating is a two part product consisting of one part epoxy resin and one part polyamine hardener. Once this product is mixed you are on a race against time. Note that if your purchase a color epoxy you are actually tinting the resin. If no color is selected a resin will dry clear.